The UConn-Technion Clean Energy Initiative facilitates the exchange of faculty and students, between UConn and the Technion-Israel Institute of Technology, to present and collaborate on research. Joint investigations are generously supported by the Satell UConn-Technion Leadership Program for Global Energy Sustainability, the Maurice G. Gamze Endowment Fund (at the American Technion Society), Larry Pitts & Phyllis Meloff, the Eileen & Jerry Lieberman UConn/Israel Global Partnership Fund, and the Grand Technion Energy Program (GTEP). UConn and Technion are recognized leaders in energy engineering and education, and both are committed to advancing global adoption of clean and efficient energy technologies. UConn’s Center for Clean Energy Engineering (C2E2), together with Technion’s Grand Technion Energy Program, provide an excellent platform to advance sustainable energy research in such areas as fuel cell systems, molten salt technology, materials corrosion, concentrated solar power life enhancement, and large-scale stationary batteries. UConn faculty interested in learning more about upcoming requests for proposals, please contact: Ugur Pasaogullari, Center Director of C2E2 (ugur.pasaogullari@uconn.edu).

Recent Projects:

Title: Highly stable and active PEM FC cathode catalyst with a protective nitride coating

Award: Satell UConn-Technion Global Energy Research Project

PIs: Prof. Jasna Jankovic (UConn) and Prof. Yair Ein-Eli (Technion)

Period: July 1, 2018 - December 31, 2020 (2 year project with a no-cost extension of 6 months)

Total Amount Awarded: $60,000

Abstract: The project approach is to impel the stability of the common commercial [Pt/C] catalyst by plating the carbon support surface with a protective film leaving Pt catalytic centers available for contacting with reagents. The material of the protective film should be corrosion resistant in the FC environment, highly conductive and hydrophobic; the film should be applied so that Pt-catalyst centers maintain accessibility for reagents. Some transition metal nitrides satisfy the conditions being promising materials for such films. Our proposal tackles these problems and offers highly conductive, hydrophobic coatings without modification of [Pt/C] catalyst preparation techniques. We propose to use ALD, as a highly promising approach that can be applied on any already existing state-of-the-art Pt/C catalyst to deposit a carbon corrosion protective layer. Therefore we are proposing a new approach of ALD coating with NbN and ZrN, materials that will provide high electronic conductivity and layer hydrophobicity, without much altering the original Pt/C catalyst. We believe that the bi-lateral project between UCon and Technion will result in novel, improved properties of the catalyst layers and has a high potential for success.

Project Summary:

The goal of the project is to improve the durability of Pt/carbon catalysts in polymer electrolyte fuel cell (PEMFC) electrodes by deposition of corrosion-resistant and electrically conductive transition metal nitride (e.g., TiN) coating selectively on the carbon surface, using atomic layer deposition (ALD) technique. The selective deposition was to be achieved by use of a protective layer of Oleylamine (OAm), which coats only Pt, but leaves carbon available for TiN coating. Our approach was aiming to develop durable and corrosion resistant fuel cells for clean energy generation. Another goal of the funding was to establish a strong collaboration between the University of Connecticut and Technion-Israel Institute of Technology, and identify future external funding opportunities for the continuation of the research.

Below are the achievements of the project up to date:

Year 1 (July 1, 2018 – June 30, 2019):

- Selective coating of Pt by OAm on model graphite electrodes was achieved. Consequent removal of OAm by heat treatment and by treatment in acetic acid was investigated, and the latter method was selected. In addition, selective coating of the graphite by TiN was achieved. The model electrodes were characterized electrochemically and microscopically.

- Yair Ein-Eli visit to UConn – Sept 2018. The visit consisted of lab visits, project updates, and a research seminar at the UConn’s Center for Clean Energy Engineering.

- The two research groups have submitted a proposal to the BSF in Nov. 2018. Despite the excellent reviews, the proposal was not funded. We will submit a revised proposal.

Year 2 (July 1, 2019 – June 30, 2020):

- The methods developed for the model graphite electrode were applied to the actual Pt/carbon powder catalyst. Challenges with the OAm deposition and ALD were encountered, due to a high surface area of the catalysts. Also, degradation of the carbon support was a challenge in high-power ALD system in Israel. The ALD deposition optimization was continued at UConn and Dr. Necmi Biyikli and his student (ALD experts) were also included in the project.

- Jankovic (UConn) organized a Workshop on Advanced Manufacturing and Characterization of Fuel Cells and Electrolyzers on Sept 23 and 24, which the Technion PI and his grad student attended. This was an international workshop involving about 50 scientists and students from US, Israel, Canada, Germany and South Africa.

- Technion student Mor Kattan visited UConn in March 2019. Him and UConn student Andres Godoy performed optimization of OAm deposition on Pt/C catalyst. Mor had to leave early due to Covid-19 pandemic.

- The labs were closed at UConn in March 2020 due to Covid-19. The planned UConn’s team trip to Israel has to be canceled. The project was extended to Dec 2020.

Project extension (July 1, 2020 – Dec 31, 2020):

- The method for OAm and TiN ALD deposition on the Pt/C catalyst were developed and optimization is in progress. Electrochemical and microscopy characterization was performed. Durability studies will be performed in the upcoming weeks.

- One Master’s thesis will be defended by Mor Kattan (Technion) in Nov 2020.

- Two publications are in preparation and will be submitted by November (1st) and March (2nd).

- PIs Jankovic and Ein-Eli will submit a research proposal to NSF-BSF in the upcoming months. The proposal will be much strengthened by the preliminary results obtained in this project.

Post-project (Jan 1, 2021 – Jan 18, 2022):

- One Master's thesis was defended by Mor Kattan (Technion) in Nov 2020.

- PIs Jankovic and Ein-Eli submitted a research proposal to NSF-BSF on 06/18/2021 titled: "Collaborative Research: NSF-BSF: Highly stable and active PEMFC catalysts with a protective nitride coating - experimental and first principle approach". The proposal received promising reviews (3 very good and 1 excellent) with suggestions how to improve the proposal. We will resubmit in the next NSF-BSF round.

Publications:

- O. Godoy, S. Ilhom, M. Kattan, P. Zarama, Y. Ein-Eli, N. Biyikli, J. Jankovic, Synthesis and Characterization of Platinum on Carbon Nanoparticles Selectively Coated with Titanium Nitride (TiN), Polymer Electrolyte Fuel Cells & Electrolyzers 21 (PEFC&E 21) - Diagnostics/Characterization Methods, MEA Design/Model issue of 240th ECS Transactions, ECS Transactions, Volume 104, Number 8, (2021).

Conference Presentations Presented:

- Godoy, S. Ilhom, M. Kattan, P. Zarama, Y. Ein-Eli, N. Biyikli, J. Jankovic, Synthesis and Characterization of Platinum on Carbon Nanoparticles Selectively Coated with Titanium Nitride (TiN), 240th ECS Conference, Orlando (virtual), October 2021.

- O. Godoy, S. Ilhom, M. Kattan, N. Biyikli, Y. Ein-Eli, J. Jankovic, Synthesis and Transmission Electron Microscopy (TEM) Characterization of Platinum on Carbon Nanoparticles Selectively Coated with Titanium Nitride (TiN), World Fuel Cell Conference, Montreal (virtual), Aug 2021.

- Godoy, S. Ilhom, M. Kattan, N. Biyikli, Y. Ein-Eli, J. Jankovic, Synthesis And Characterization of Platinum on Carbon Nanoparticles Selectively Coated with Titanium Nitride (TiN), Fall MRS Meeting, Boston (virtual), Nov 29-Dec 2, 2021

We would like to thank the Satell Family Foundation, the Maurice G. Gamze Endowed Fund, Larry Pitt and Phyllis Meloff, and the Eileen and Jerry Lieberman UConn/Israel Partnership Fund for this generous financial support.

Title: SOFC cathode poisoning from airborne impurities: Mechanism and mitigation

PIs: Prof. Prabhakar Singh (UConn) and Prof. Yoed Tsur (Technion)

Period: July 1, 2018 - Ongoing

Total Amount Awarded: $60,000

Abstract: The proposed UConn-Technion research program capitalizes on the combined strength and past working experience of the PIs and existing laboratory capabilities at Technion and UConn. The overall technical objective of the proposed collaborative research program is to mitigate SOFC cathode poisoning mechanisms originating from the presence of air borne intrinsic and extrinsic impurities entering the electrochemically active cell stack. It is also the objective of the research effort to identify, synthesize, test and validate multifunctional getters for the co-capture of air borne intrinsic and extrinsic impurities (Cr, S, B and Si) and demonstrate through transpiration and electrochemical tests, that the developed getters effectively reduce long term electrochemical performance degradation. The research team will utilize existing experimental facilities at both institutions to synthesize high surface area nano-fibrous and nano-particulate high surface area oxide composites and develop getter architectures for incorporation in the SOFC stack and balance of plant (BOP) sub-systems. It is envisioned that in-depth analysis of EIS data, synthesis of high surface area oxide nano-rods and particles as well as characterization of the getter by HRTEM will be performed at Technion. Electrochemical and transpiration tests, getter formulations and posttest characterization will be performed at UConn. The envisioned collaboration between the two institutions will strengthen the information exchange, dissemination of information, training of faculty and students.

Publications:

As of January, 2022, the collaborative program focused on technical discussion pertaining to air borne trace contaminants and their removal utilizing cost effective getters. A manuscript titled “3-dimentional foam to capture contaminants from air and interconnects in solid oxide fuel cells” has been written and is currently under review. Due to the on-going pandemic, any faculty or student exchange between two institutions has been on hold. We plan to invite professor Tsur and his students at the earliest opportune time.

Title: NiM-CeOx/C catalyst synthesis and characterization

PIs: Prof. Radenka Maric (UConn) and Prof. Dario R. Dekel (Technion)

Period: July 1, 2018 - December 31, 2021

Total Amount Awarded: $75,000

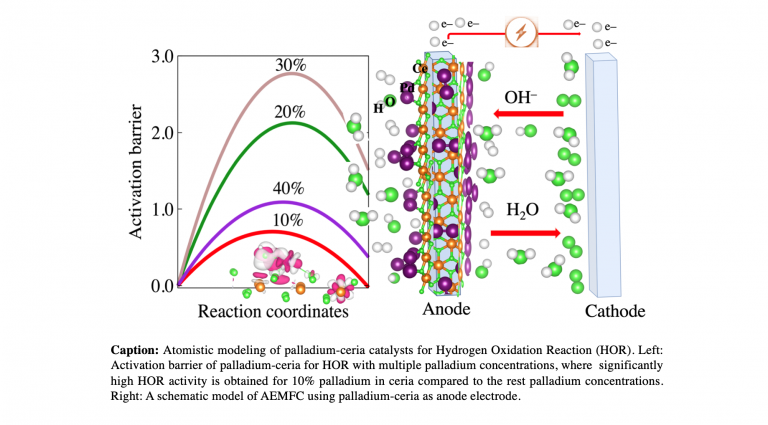

Abstract: Anion exchange membrane fuel cells (AEMFCs) have received increasing attention as this technology has the potential to replace expensive platinum and platinum alloy materials currently used in fuel cell electrodes, significantly reducing the cost of fuel cell devices. Recently, significant progress has been made in improving material components for AEMFCs in particular cell hardware, membranes, ionomers and cathode catalysts for the oxygen reduction reaction. However, the sluggish anodic hydrogen oxidation reaction (HOR) kinetics of electrocatalysts under alkaline conditions have limited the development of affordable Pt-free catalysts and AEMFC technology is still awaiting new advanced anode catalytic materials to fulfill its potential. This goal represents one of the major two challenges in the today’s state-of the-art AEMFC technology. Only a few examples of Pt-free AEMFCs have been demonstrated until today, most of them with relatively low power output. Using a new bifunctional catalyst approach, consisting of a ceria-Pd interface, we have very recently showed a significant improvement in the HOR kinetics, reaching a record high Pt-free AEMFC performance of ca. 500 mW cm-2. This bifunctional catalyst approach promises to overcome the major HOR challenge of the AEMFC technology. However, little is known about bifunctional catalysts, and no satisfactory method has been defined that achieves the very highly active ceria-Pd catalyst that is required to overcome the cost challenges. We propose here to use a unique advanced technology that will allow us to study and optimize the ceria-Pd electrochemical interfacial properties. 1) Use reactive spray deposition technology (RSDT) to control atomic-level mixing during catalyst creation and use this control to design catalysts with an optimum number of identical active sites; 2) Manufacture catalysts and electrodes to maximize power output of Pt-free based AEMFCs.

Project Outcomes:

- The team achieved Hydrogen oxidation reaction (HOR) performance of Ni based catalyst superior to the state of the art model as shown in the published literature for anion exchange membrane fuel cell (AEMFC). Our test article is a 3 nm Ni/CeO2/C catalyst which achieved a mass activity of 14.92 mA/mg Ni which is superior to the results of 18 of the best results that are published best literature. All samples are fabricated by the Reactive Spray Deposition Technology (RSDT) process and results are from RDE tests. A paper on this work has been written and is in internal review.

Funding for this work has been increased to support continuing through the end of this year.

Publications:

- “Palladium-ceria nanocatalyst for hydrogen oxidation in alkaline media: optimization of the Pd-CeO2 interface”; Haoran Yu, Elena S. Davydova, Uri Ash, Hamish A. Miller, Leonard J. Bonville, Dario R. Dekel, and Radenka Maric; Nano Energy 57, 820-826, 2019. (IF=13.1) # Over 50 citations (source: Google Scholar)

- “Atomistic insights into the hydrogen oxidation reaction of palladium-ceria bifunctional catalysts for anion-exchange membrane fuel cells”; Sanjubala Sahoo, Dario R. Dekel, Radenka Maric, and S. Pamir Alpay; ACS Catalysis 11, 2561-2571, 2021. (IF=12.3)

- “Advanced Nickel-based Catalysts for the Hydrogen Oxidation Reaction in Alkaline Media Synthesized by Reactive Spray Deposition Technology: Study of the Effect of Particle Size”; Zhiqiao Zeng, Jiale Xing, Leonard Bonville, Dario R. Dekel, Radenka Maric, and Stoyan Bliznakov; submitted to Int. J. Hydrogen Energy, Feb 1, 2023. (IF=7.1) (under review)

Conference Presentations Presented:

- Haoran Yu, Elena S. Davydova, Uri Ash, Hamish A. Miller, Leonard Bonville, Dario R. Dekel and Radenka Maric; “Palladium-ceria nanocatalyst for hydrogen oxidation in alkaline media: optimization of the Pd-CeO2 interface”; Contributed talk presented at the 235th Electrochemical Society Meeting, Dallas, TX, USA, May 26-31, 2019.

- Sanjubala Sahoo, Dario R. Dekel, Radenka Maric, and Pamir Alpay; "Bifunctional Palladium-Ceria Catalysts for Hydrogen Oxidation Reaction"; Contributed talk at the 240th ECS Meeting, (Online) Orlando, USA, October 10-14, 2021